Šmajstrla- buckwheat mill

Product sorting

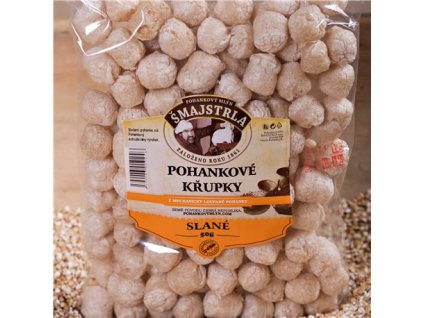

List of products

In our mill in Kopane in Frenstat pod Radhostem, buckwheat has been husked since 1861 in a mechanical way in which vitamins are not degraded. It is our wish that the buckwheat continues to bring health to the people. Health is still the greatest wealth of every person.

After a telephone appointment we can arrange excursions with the sale of buckwheat products.

We buy cleaned, dried unpeeled Czech buckwheat for food processing.

Every time I think about grandfather Francis, I think of an image of a spring afternoon in 1953. As a six year old boy I was sitting on country lane, watching him carefully plowing soil in the field, literally cuddling each lump of clay, tore weeds and picking stones.  Stones were on the edge of the field, where they formed some kind of dam. In Wallachia people call them "hromadiska".

Stones were on the edge of the field, where they formed some kind of dam. In Wallachia people call them "hromadiska".

My boyhood experiences that obviously influenced my whole life I actually owe to an accident. I started my school in Petrovice near Karvina with teacher Olga Belikova. Soon I fell sick with a whooping cough and on the recommendation of a doctor Rottaegla mom took me to my grandfather Francis to Frenstat pod Radhostem as she said to breathe fresh air.

Back in my childhood I first met with the cultivation of buckwheat and its sowing, harvesting and threshing. Grandfather Francis explained that buckwheat needs a freshly plowed land because it germinates before the weeds. "It is a big mistake to plow fields in the autumn and in the spring only drag it before sowing. The weeds will infect the entire field ahead of the buckwheat." he said. He never fertilized fields before sowing, so plants would not grow unnecessarily high and would not sink to the ground. The buckwheat was always sown where in the previous year potatoes or beets were planted. These ancestral wisdoms which my grandfather Francis passed down to me were kept somewhere in my head and later on, when I decided to continue Smajstrla's family mill tradition I began to recall.

One day even I have put miller apron on as the fourth miller of the Smajstrl family. Father Arnost died suddenly and there were plenty of pending orders in the mill. "You have to finish it Zdenek as no one else understands these machines" my neighbors told me and I was convinced. I had studied at the Pedagogical Institute and had spent thirty years of teaching experience at the Tatra Koprivnice School.

In the old mill, after my father, I finally milled the buckwheat for a year and a half. It was a long time for me to go back to my childhood at least in my memories and again I could watch grandfather Francis how in the spring he plows the fields before sowing or before the storm he hustle horses and carriage with buckwheat sheafs. In moments of leisure I browsed my father's notes. He wrote a variety of data about buckwheat in a thick black notebook. I saw him gradually becoming aware that this cereal will become an important food in rational nutrition in the future due to its healing effects. Together with son Vladimir, my older brother, he even organized a conference in Nitra which was visited by planters and buckwheat processors from all over the country. In front of the full auditorium father Arnost lectured on a special variety of buckwheat called pyra which has good fertility in the mountain conditions the same grain size and excellent taste qualities.

I succumbed to the mill's atmosphere after the year and a half and did not return to teaching. I knew that if I wanted to continue the miller's tradition I had to modernize the mill. Similarly as did my grandfather Francis. There was remodeling. Only the pillars and the roof were left from the original building. Inside of the mill is covered with ceramic tiles. I had to replace machines for peeling buckwheat. They were more like museum exhibits. My classmate Josef Gajdusek from Papratna helped me build the new machines. He still works as a technician for the machines in the mill today. The line he put into operation will process three tons of buckwheat per shift. Grandfather Francis put everything into his work yet he did not manage more than a ton per day. Well, progress is progress. But he certainly would not have envied me. Rather, he would be delighted.